- Home Page

- Company Profile

-

Our Products

- FRP Pultruded Products

- FRP / GRP Moulded Gratings

- FRP / GRP Decorative Lighting Poles

- FRP Pultrusion Profile

- FRP / GRP Canopies

- FRP / GRP Cable Tray

- Fiber Glass Products

- FRP Ladder

- FRP Custom Ladders & Structure

- GRP Ladders

- Fiberglass Ladder

- FRP ladder

- Fiberglass Self Supported Ladder

- Fiberglass Self-Supported Two Way Ladder

- Fiberglass Wall Supported Ladder

- Fiberglass Self Supported Platform Ladder

- Fiberglass Step Stand Ladder

- Fiberglass Extension Telescopic Ladder

- Fiberglass Mobile Platform Ladder

- Fiberglass Maintenance Platform Ladder

- Fiberglass Manhole Ladder

- Fiberglass Mobile Telescopic Platform Ladder

- Fiberglass Mobile Telescopic Tilting Ladder

- Fiberglass Safety Caged Ladder

- Fiberglass Self Supported Ladders

- Two Side Mechanical Step Ladder

- Fiberglass Platform Ladder

- Fiberglass Mobile Platform Ladders

- Safety Cage Ladder

- FRP Ladders

- FRP Wall Support Extension Ladder

- Fiberglass Safety Ladders

- Step Folding Ladder

- FRP Access Ladder

- FRP Multipurpose Ladder

- Fiber Reinforced Polymer Ladders

- FRP Safety Ladders

- Warehouse Mobile Platform Ladders

- Fencing Railings

- Cable Cleat

- Material Holding Clamps

- GRP Profiles

- Cooling Towers Solutions

- FRP Profiles

- Fiberglass Structural Beams

- Fiberglass Pultruded Standard Profiles

- Fiber Reinforced Profile

- FRP Angle Profile

- FRP Box Profile

- Fibre Reinforced Plastic Profile

- FRP Profile

- Aeron Glass Fiber Profiles

- FRP Tube Profile

- FRP C Channel Profile

- FRP Pultruded Profile

- FRP Channel

- FRP Structural Profile

- FRP Cooling Tower Profiles

- FRP Square Pultruded Profile

- FRP Epoxy Pultruded Profiles

- FRP Structural Shapes

- Fiberglass Profile

- Aeron FRP Profile

- FRP Hollow Section

- Carbon Fiber Rod

- Solar Mounting Structure

- Cable Trays

- FRP Cable Trays

- Fiber Reinforced Ladder Cable Tray

- Electrical Cable Tray

- Ladder Cable Tray

- Cable Tray with Cover

- FRP Cable Tray with Cover

- Fiberglass Cable Trays

- FRP Ladder Cable Trays

- Cable Tray Cover

- Fibre Reinforced Plastic Cable Tray

- FRP Coupler Splice Plate

- FRP Adjustable Splice Plates

- Glass Fiber Cable Tray

- FRP Ladder Cable Tray

- FRP Flexible Cable Tray

- FRP Ladder Type Cable Tray

- FRP Gratings

- Walkway FRP Grating

- FRP Molded Grating

- Rectangular FRP Grating

- FRP Pultruded Grating

- FRP Cover Top Grating

- FRP Platform Grating

- Composite Grating

- FRP Inbuilt Grit Top Grating

- FRP Concave Top Grating

- FRP Grating

- Fiber Reinforced Grating

- Molded Fiberglass Grating

- FRP Pultruded Fiberglass Grating

- Concave Surface FRP Grating

- FRP Walkway

- FRP Walkway for Rooftop

- Glass Fiber Grating

- Commercial FRP Gratings

- FRP Floor Grating

- Fiberglass Floor Plate

- Fiberglass Grating Systems

- FRP Handrail

- FRP Module Solar Panel Mounting Structure

- GRP Clamp

- Light Poles

- FRP Rod Strength Member

- FRP Sheet

- FRP Products

- FRP Canopies

- GRP Gratings

- GRP Applied Grit Top Grating

- GRP Grating Systems

- GRP Inbuilt Grit Grating

- GRP Walkway Grating

- Industrial GRP Grating

- Square GRP Grating

- GRP Pultruded Grating

- GRP Floor Grating

- GRP Grating

- Fiberglass Molded GRP Grating

- GRP Mesh Gratings

- GRP Fiberglass Oil Platform Grating

- Pultruded Fiberglass Grating

- GRP Oil Platform Grating

- GRP Cover Top Grating

- GRP Molded Grating

- GRP Cable Tray

- Electrical GRP Cable Tray

- Glass Fiber Reinforced Cable Tray

- Electrical GRP Cable Tray

- GRP Cover Perforated Cable Tray

- GRP Cable Tray with Cover

- GRP Ladder Type Cable Tray

- Straight Flange GRP Cable Trays

- GRP Waterproof Cable Trays

- GRP Pultruded Cable Trays

- GRP Cable Tray

- GRP Cable Trays with Cover

- Pultruded Electrical GRP Cable Tray

- GRP Ladder

- FRP Safety Marker

- Carbon Fiber Products

- FRP Cross Arm

- GRP Products

- FRP Stair Tread

- FRP I Beam

- FRP Rebar

- FRP Tank

- Extra Links

- Contact Us

FRP Trench Covers

125 INR/Meter

Product Details:

- GSM 2000 GSM

- Density 1.8 Gram per cubic centimeter(g/cm3)

- Temperature -40C to +80C

- Usage & Applications Trench Covering, Cable Duct Protection, Walkway Safety

- Shape Rectangular

- Glass Type E-Glass

- Coating Type Anti-Corrosive, UV Resistant

- Click to view more

X

FRP Trench Covers Price And Quantity

- 50 Meter

- 125 INR/Meter

- <0.1%

- 210 MPa

- Grey, Green, as per requirements

- Yes

- Modular, Easy to handle

- Low

- Smooth or Anti-slip

- High

- Up to 2 Tonne

- Reinforced

FRP Trench Covers Product Specifications

- For Trenches And Ducts Purpose

- Rectangular

- E-Glass

- 2000 GSM

- -40C to +80C

- 1.8 Gram per cubic centimeter(g/cm3)

- Pultrusion Moulding

- Trench Covering, Cable Duct Protection, Walkway Safety

- For Trenches And Ducts Purpose

- Anti-Corrosive, UV Resistant

- 0.25 W/mK

- 10 mm, Customizable

- Painted

- FRP

- 457.2 - 1016 Millimeter (mm)

- Trench Covers

- 457.2 - 1016 mm (Length), Custom Width & Height

- <0.1%

- 210 MPa

- Grey, Green, as per requirements

- Yes

- Modular, Easy to handle

- Low

- Smooth or Anti-slip

- High

- Up to 2 Tonne

- Reinforced

FRP Trench Covers Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 500 Meter Per Day

- 1 Week

- All India

Product Description

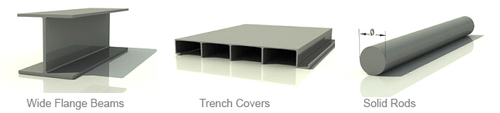

FRP Trench Covers / Wide Flange Beams / Solid Rods

Under the exemplary leadership and guidance of our expert professionals, we have been able to emerge as a trusted manufacturer and supplier of FRP Trench Covers / Wide Flange Beams / Solid Rods. These covers are used in building construction works. To manufacture these covers, our diligent workforce uses premium quality FRP. Available in different sizes and specifications, our FRP Trench Covers / Wide Flange Beams / Solid Rods are highly demanded in the market. We offer these covers at reasonable prices.

Features:

- Light weight

- Sturdy in nature

- Breakage free

AERON COMPOSITE" Trench Covers append to our variety of products particularly manufactured for the generation of power and its distribution markets.

Trench Covers are conveniently handled considerably dipping installation costs. Weighing lower than 17 Kgs/m, Trench Covers remove the requirement for weighty lifting gear, dipping the number of requirement of site workers making a very rapid and convenient installation.

Advantages:

- Outstanding Corrosion Resistance

- Abrasion Resistant

- 65% less weight than Steel

- Non-Conductive

- Slip Resistant

- Long and Maintenance Free Life

- Easy to manufacture and light weight

- Better Ergonomics

- Convenient to handle and non- expensive to install

- Enhances safety, diminishes slips and falls

Specification

| Density | 1.6g/cm3 |

| Tray Type | Perforated Cable Tray |

| Thickness | 3 mm - 6 mm |

| Brand | Aeron |

| Material | Fiber Reinforced Plastic (FRP) |

| Tensile Strength | 2500Mpa |

Superior Load Bearing and Safety

FRP trench covers are constructed for robust performance, safely supporting up to 2 tonnes and mitigating risks with smooth or anti-slip surfaces. Reinforced edges and high flexural strength keep both pedestrians and equipment secure, while anti-corrosive and UV-resistant coating maximizes longevity even in harsh outdoor settings.

Versatile Applications and Modular Installation

These covers are suitable for a range of applications including trench covering, cable duct protection, and walkway safety. Their modular design allows for quick, easy installation and adaptability to custom lengths, widths, and heights, ensuring a perfect fit for specific trench and duct requirements.

Low Maintenance and Weather Resistance

With a fire-resistant structure, minimal water absorption, and resistance to corrosion and UV degradation, FRP trench covers require minimal maintenance. They withstand temperatures from -40C to +80C, making them reliable for use in various industrial climates throughout the year.

FAQs of FRP Trench Covers:

Q: How is the FRP Trench Cover installed and handled?

A: FRP trench covers are modular and designed for straightforward handling. Their lightweight nature allows for easy placement and adjustment without specialized equipment, making installation efficient even in large-scale projects.Q: What benefits does the anti-slip finish offer?

A: The anti-slip finish significantly improves traction, reducing the risk of slips or falls. This feature is especially effective in areas exposed to moisture, ensuring walkway safety for personnel working around trenches and ducts.Q: When is it recommended to use these trench covers for cable protection?

A: Use FRP trench covers for cable protection whenever enhanced safety, load-bearing, and durability are required, especially in commercial, industrial, or outdoor applications where cables must be shielded from damage and environmental exposure.Q: Where can these trench covers be applied?

A: These covers are ideal for use in a variety of locations including factories, construction sites, walkways, and utility zones. Their customizable dimensions allow them to fit trenches and ducts in diverse settings across industrial and commercial sectors.Q: What makes FRP trench covers resilient to environmental challenges?

A: The covers feature high-density FRP with anti-corrosive and UV-resistant coatings, minimal water absorption, and fire resistance. This combination allows them to withstand extreme temperatures, moisture, and chemical exposure while maintaining structural integrity.Q: How does the manufacturing process ensure product quality?

A: Manufactured using pultrusion moulding with E-Glass, the process enhances flexural strength and impact resistance while maintaining precise dimensions. The painted surface treatment and reinforced edges further increase durability and performance.Q: What kind of maintenance is required for FRP trench covers?

A: Routine cleaning and visual inspections suffice, as their non-porous and corrosion-resistant surfaces require minimal upkeep. This results in lower maintenance costs and sustained functionality over time.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese