- Home Page

- Company Profile

-

Our Products

- FRP Pultruded Products

- FRP / GRP Moulded Gratings

- FRP / GRP Decorative Lighting Poles

- FRP Pultrusion Profile

- FRP / GRP Canopies

- FRP / GRP Cable Tray

- Fiber Glass Products

- FRP Ladder

- FRP Custom Ladders & Structure

- GRP Ladders

- Fiberglass Ladder

- FRP ladder

- Fiberglass Self Supported Ladder

- Fiberglass Self-Supported Two Way Ladder

- Fiberglass Wall Supported Ladder

- Fiberglass Self Supported Platform Ladder

- Fiberglass Step Stand Ladder

- Fiberglass Extension Telescopic Ladder

- Fiberglass Mobile Platform Ladder

- Fiberglass Maintenance Platform Ladder

- Fiberglass Manhole Ladder

- Fiberglass Mobile Telescopic Platform Ladder

- Fiberglass Mobile Telescopic Tilting Ladder

- Fiberglass Safety Caged Ladder

- Fiberglass Self Supported Ladders

- Two Side Mechanical Step Ladder

- Fiberglass Platform Ladder

- Fiberglass Mobile Platform Ladders

- Safety Cage Ladder

- FRP Ladders

- FRP Wall Support Extension Ladder

- Fiberglass Safety Ladders

- Step Folding Ladder

- FRP Access Ladder

- FRP Multipurpose Ladder

- Fiber Reinforced Polymer Ladders

- FRP Safety Ladders

- Warehouse Mobile Platform Ladders

- Fencing Railings

- Cable Cleat

- Material Holding Clamps

- GRP Profiles

- Cooling Towers Solutions

- FRP Profiles

- Fiberglass Structural Beams

- Fiberglass Pultruded Standard Profiles

- Fiber Reinforced Profile

- FRP Angle Profile

- FRP Box Profile

- Fibre Reinforced Plastic Profile

- FRP Profile

- Aeron Glass Fiber Profiles

- FRP Tube Profile

- FRP C Channel Profile

- FRP Pultruded Profile

- FRP Channel

- FRP Structural Profile

- FRP Cooling Tower Profiles

- FRP Square Pultruded Profile

- FRP Epoxy Pultruded Profiles

- FRP Structural Shapes

- Fiberglass Profile

- Aeron FRP Profile

- FRP Hollow Section

- Carbon Fiber Rod

- Solar Mounting Structure

- Cable Trays

- FRP Cable Trays

- Fiber Reinforced Ladder Cable Tray

- Electrical Cable Tray

- Ladder Cable Tray

- Cable Tray with Cover

- FRP Cable Tray with Cover

- Fiberglass Cable Trays

- FRP Ladder Cable Trays

- Cable Tray Cover

- Fibre Reinforced Plastic Cable Tray

- FRP Coupler Splice Plate

- FRP Adjustable Splice Plates

- Glass Fiber Cable Tray

- FRP Ladder Cable Tray

- FRP Flexible Cable Tray

- FRP Ladder Type Cable Tray

- FRP Gratings

- Walkway FRP Grating

- FRP Molded Grating

- Rectangular FRP Grating

- FRP Pultruded Grating

- FRP Cover Top Grating

- FRP Platform Grating

- Composite Grating

- FRP Inbuilt Grit Top Grating

- FRP Concave Top Grating

- FRP Grating

- Fiber Reinforced Grating

- Molded Fiberglass Grating

- FRP Pultruded Fiberglass Grating

- Concave Surface FRP Grating

- FRP Walkway

- FRP Walkway for Rooftop

- Glass Fiber Grating

- Commercial FRP Gratings

- FRP Floor Grating

- Fiberglass Floor Plate

- Fiberglass Grating Systems

- FRP Handrail

- FRP Module Solar Panel Mounting Structure

- GRP Clamp

- Light Poles

- FRP Rod Strength Member

- FRP Sheet

- FRP Products

- FRP Canopies

- GRP Gratings

- GRP Applied Grit Top Grating

- GRP Grating Systems

- GRP Inbuilt Grit Grating

- GRP Walkway Grating

- Industrial GRP Grating

- Square GRP Grating

- GRP Pultruded Grating

- GRP Floor Grating

- GRP Grating

- Fiberglass Molded GRP Grating

- GRP Mesh Gratings

- GRP Fiberglass Oil Platform Grating

- Pultruded Fiberglass Grating

- GRP Oil Platform Grating

- GRP Cover Top Grating

- GRP Molded Grating

- GRP Cable Tray

- Electrical GRP Cable Tray

- Glass Fiber Reinforced Cable Tray

- Electrical GRP Cable Tray

- GRP Cover Perforated Cable Tray

- GRP Cable Tray with Cover

- GRP Ladder Type Cable Tray

- Straight Flange GRP Cable Trays

- GRP Waterproof Cable Trays

- GRP Pultruded Cable Trays

- GRP Cable Tray

- GRP Cable Trays with Cover

- Pultruded Electrical GRP Cable Tray

- GRP Ladder

- FRP Safety Marker

- Carbon Fiber Products

- FRP Cross Arm

- GRP Products

- FRP Stair Tread

- FRP I Beam

- FRP Rebar

- FRP Tank

- Extra Links

- Contact Us

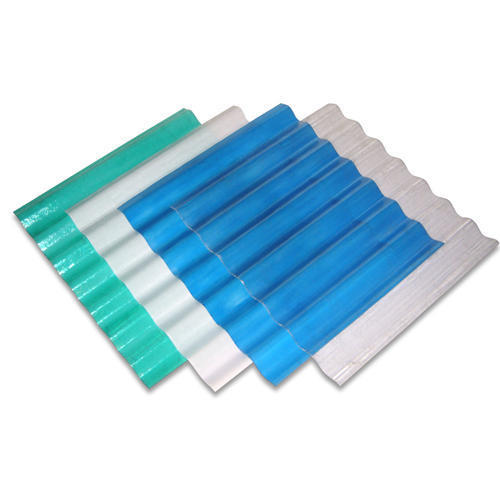

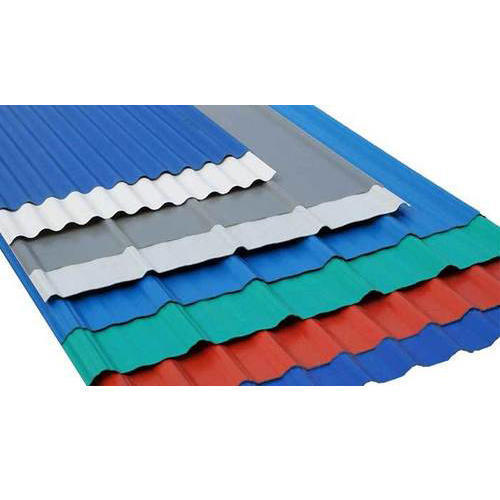

FRP Sheet

750 INR/Meter

Product Details:

- Shape Rectangle

- Usage Industrial

- Material FRP

- Size Standard

- Application Exterior Decor

- Product Type FRP Sheet

- Surface Treatment Coated

- Click to view more

X

FRP Sheet Price And Quantity

- 50 Meter

- 750 INR/Meter

FRP Sheet Product Specifications

- FRP Sheet

- Coated

- Standard

- Rectangle

- Exterior Decor

- FRP

- Industrial

FRP Sheet Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 500 Meter Per Day

- 1 Week

- All India

Product Description

Product details

| Color | Multicolor |

| Warranty | 5-10* Years |

| Shape | Rectangular,Square |

| Thickness | 3mm,2mm,1mm,4mm |

| Width | 1500 mm(Stretch) |

| Unit Weight | Depend on type |

| Tolerance | + or - 10% (As per standard) |

| Resin | G.P/ Roof lite/ Isophthalic/ Vinylester |

| Length | No restriction |

| Glass Content | Not less then 25% |

| Gel Coat | Top side with any resin(optional) |

| Capacity | 50,000 Sq.mtr/month |

High-Performance FRP Sheets for Exterior Decor

Our FRP sheets are engineered with robust material and advanced coating, making them perfectly suited for outdoor industrial decor. With a rigid structure and excellent transparency, these sheets enhance both aesthetic appeal and durability, ensuring a longer lifespan even under harsh environmental conditions.

Versatility for Industrial Applications

Whether the project demands strength or visual clarity, these FRP sheets meet a variety of industrial needs. Standard sizing and rectangular shape contribute to seamless installation across diverse settings, providing flexibility for manufacturers and suppliers serving the Indian market.

FAQs of FRP Sheet:

Q: How are FRP sheets used in exterior industrial decor?

A: FRP sheets are commonly used as protective and decorative panels on building exteriors. Their transparency and rigidity make them ideal for enhancing aesthetics while providing structural resilience, especially in industrial settings exposed to varying weather conditions.Q: What is the process involved in manufacturing FRP sheets?

A: FRP (Fiber-Reinforced Polymer) sheets are produced by combining fiberglass with polymer matrices, followed by coating. The process includes molding the material into standard sizes and shapes, ensuring consistent thickness (1-4 mm) and transparency while maintaining rigid hardness.Q: When should FRP sheets be chosen over other materials?

A: FRP sheets are ideal when you require a lightweight, transparent, weather-resistant, and rigid panel for industrial exterior applications. Their superior corrosion resistance and easy maintenance make them preferred over traditional metal or plastic sheets.Q: Where are these FRP sheets commonly supplied and installed?

A: These sheets are exported, manufactured, and distributed across India and are typically installed in factories, warehouses, plant exteriors, and other industrial facilities requiring durable decorative solutions.Q: What benefits do coated FRP sheets offer for industrial users?

A: Coated FRP sheets deliver enhanced weather protection, prolonged service life, and improved visual appeal. Their rigidity ensures stability, while the lightweight nature simplifies handling and installation, ultimately reducing overall project costs.Q: How should FRP sheets be maintained for long-term performance?

A: Regular cleaning with non-abrasive solutions and periodic inspection for any surface damage will help maintain their appearance and structural integrity. The coated surface further minimizes maintenance compared to uncoated alternatives.Q: Can FRP sheets be customized for special industrial projects?

A: Yes, while standard sizes are available, manufacturers can customize dimensions, transparency level, and surface coatings to meet the specific requirements of unique industrial projects.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese